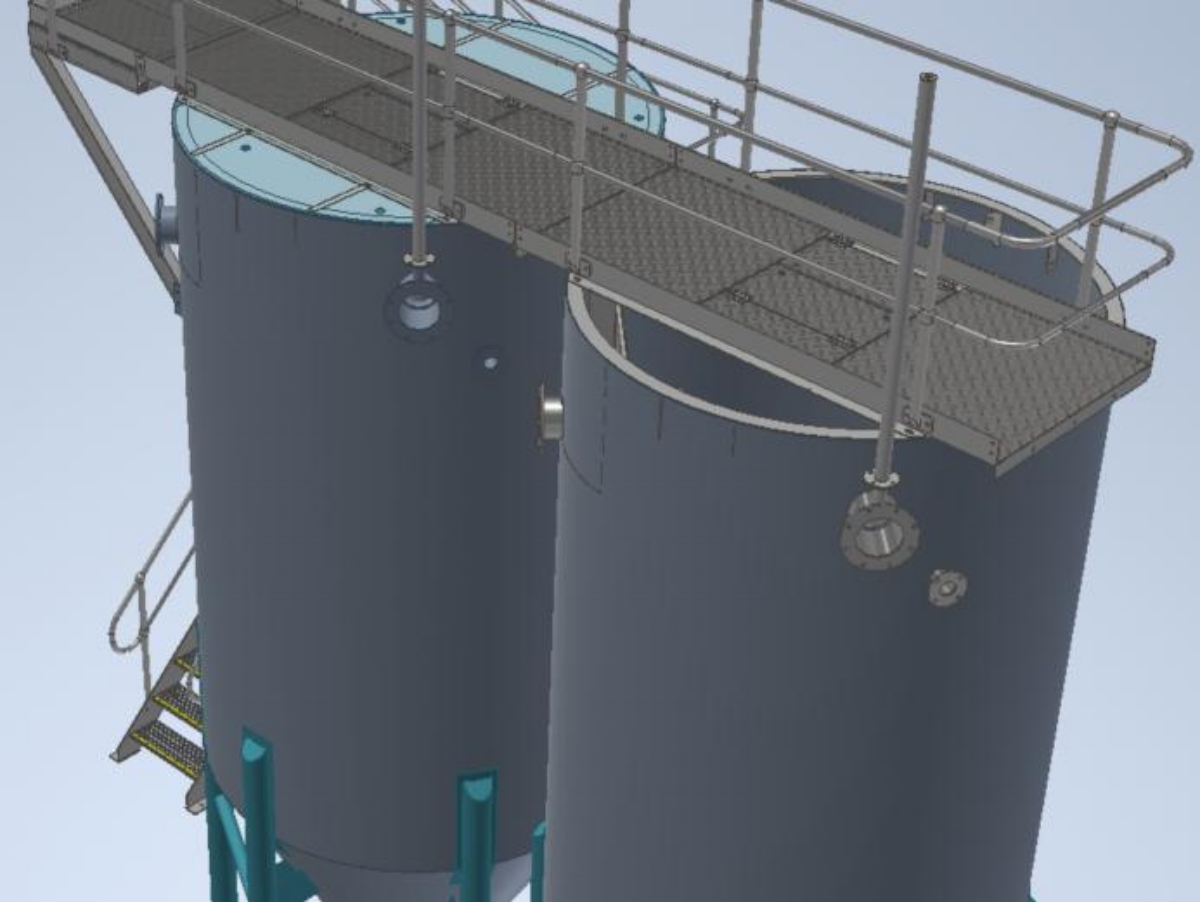

CWUF Sand Filters

The Siebtechnik Tema Continuously Washing Up Flow (CWUF) sand filters are deep bed gravity filters that continuously self-clean during operation. This means you do not need any back washing equipment (pumps, tanks, piping, instrumentation etc.) and simplifies operation and maintenance since filters do not need to be shut down for backwash cycles. Our filters have a deep sand bed (effective depth of 2 m) that provides excellent filtration and sludge storage capacity, compared to conventional media filters.

Our CWUF sand filters are 100% Australian made, in our factory in Revesby (greater Sydney area, NSW). They are a well proven technology, where Siebtechnik Tema has supplied more than 155 CWUF filter units (of various sizes) over the past 30 years for various applications.

The CWUF filter is suitable for many applications; the main two being purification of raw water for drinking and process purposes, and purification of waste water and industrial effluents.

How it works

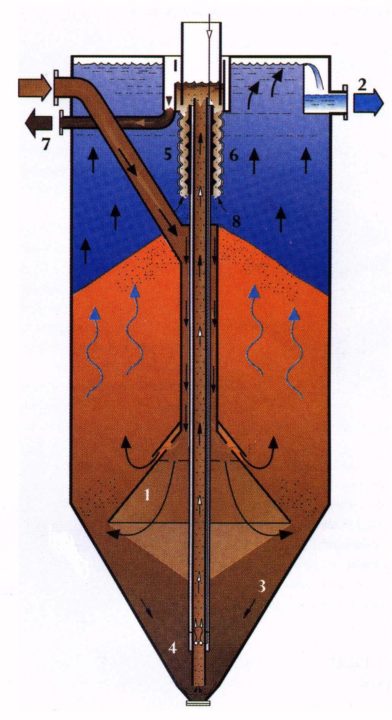

The CWUF filter works on the upstream principle. The water that is to be treated is admitted to the inlet distributor (1) in the bottom section of the filter. The water flows up through the sand bed, where it is cleaned and then leaves the filter through the filtrate outlet (2) at the extreme top. The pollutants remain in the sand bed. The contaminated sand is transported from the bottom cone (3) by means of the air-lift pump (4) to the sand washer (5) at the top of the filter. Cleaning of the filter sand begins in the air-lift pump, in which the intense stirring action releases the dirt particles from the grains of sand. The contaminated sand flows out of the pump outlet and drops down into the washing labyrinth (6), where it is washed by a moderate flow of cleaned water. The contaminants are entrained upwards to the washing water outlet (7). The grains of sand, which are heavier than the contaminants, drop down towards the sand bed (8) which is thus in a constant state of downward movement through the filter.

The operation of the filter – both cleaning of the water and cleaning of the sand – is continuous. As a result, the filter need never be shut down.

Material of Construction

We carefully choose the material of construction, depending on the unique site conditions and feed water characteristics, where the most common materials are:

- Epoxy coated mild steel

- 316 stainless steel

Site requirements

Compressed air is required on site, which must be supplied to the control panel at 5-7 bar supply pressure. Air flow required depends on the filter size and can be advised after model selection.

Optional extras

Every CWUF filter includes: sand media, filter lids and a local control panel.. We generally offer the following optional extras:

- Platform and staircase to provide access to the top for operational and maintenance purposes

- On site installation by our service technicians

- On site commissioning assistance by one of our engineers

Advantages

CONTINUOUS OPERATION

- No need to shut down for back washing

SIMPLICITY

- No backwash water storage

- No backwash water pumps

- Filtration process is automated without the need for automatic valves

- Single media

- No moving parts, simple operation

- Minimum of wear and tear

FLEXIBILITY

- Modular form allows easy expansion

- Space-saving

- Can be free-standing or in concrete tank

OPERATING ECONOMY

- Low pressure drop

- Low air consumption

- Automated, trouble-free operation

- Low maintenance

- No spare parts