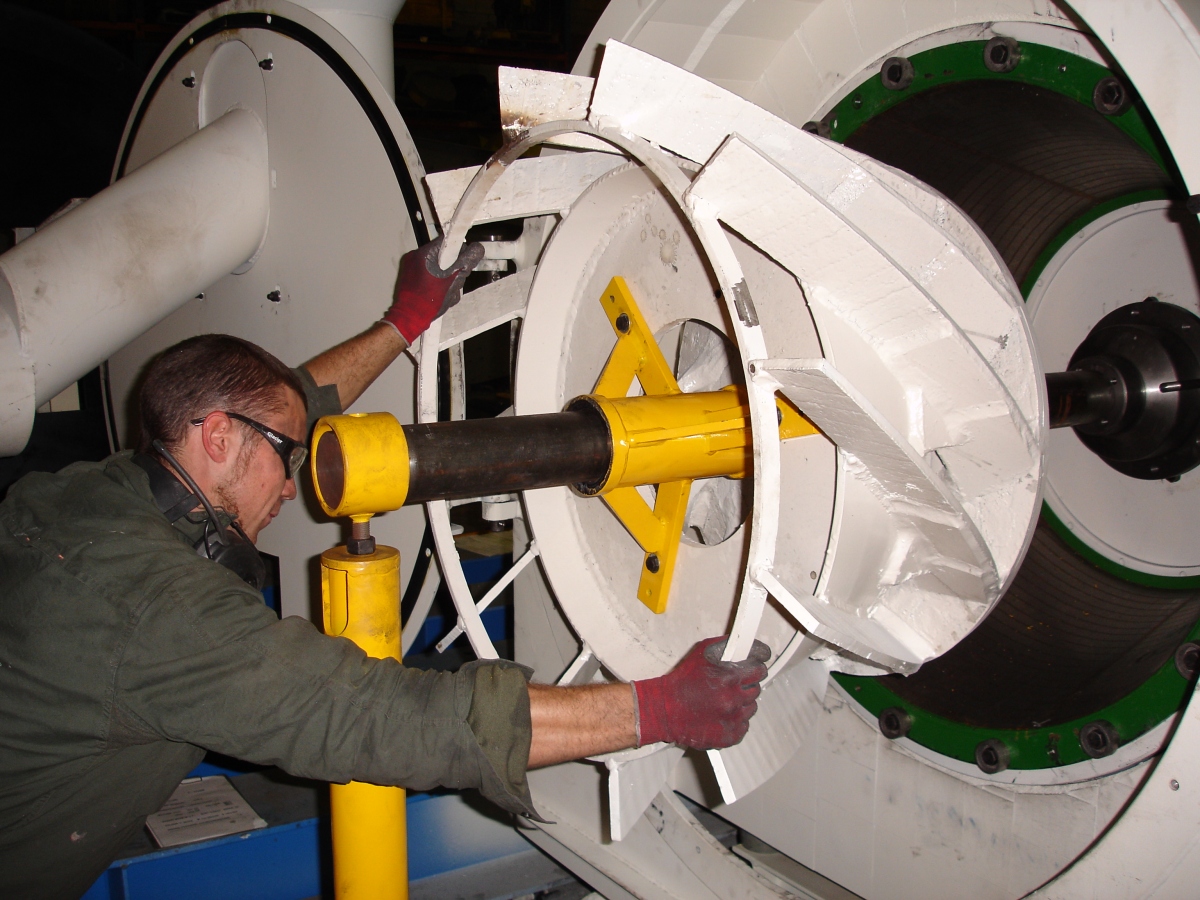

Service and Maintenance

Service and Maintenance

Your basis for high availability and reliable production

SIEBTECHNIK TEMA provides a single solution for all your on-site service and maintenance requirements in Australia. Our field service crews are experienced engineers and technicians who:

- Perform scheduled preventative maintenance and also offer 24 hour breakdown emergency assistance

- Are compliant with all applicable Australian site specific and Workplace Health & Safety (WH&S) standards

- Perform service work in a multitude of industries, including mining, water treatment and food industries

- Minimise unscheduled equipment and production downtime

- We offer service and maintenance solutions, not only for our Siebtechnik Tema machines, but also for equipment from various other Original Equipment Manufacturers (OEM’s)

Our service branches are strategically located throughout Australia, in all main mining areas, allowing us to meet all our customers service and maintenance needs. Additionally, we carry high stock levels of various spare parts and consumables for various equipment, ensuring short lead times at all times.

Availability of spare parts

With SIEBTECHNIK TEMA you have the OEM by your side, where we stock standard spare parts, especially components for the centrifuge drive/bearing system. Our staff would be pleased to analyse your stock on site and – depending on machine loads and production conditions – prepare an individual spare parts package to minimise machine down-times. Complete service and repair kits additionally systematise and simplify maintenance.

Local service

SIEBTECHNIK TEMA specialists use their worldwide and local experience to support you with service and maintenance work. In Australia our service branches are strategically located in all main mining areas, allowing us to coordinate service assignments at your site on short notice.

Preventive maintenance

“Preventive maintenance” is the most important instrument for early identification of equipment wear and damage, ultimately leading to unscheduled stoppages which result in loss of production, if not identified and rectified. Here SIEBTECHNIK TEMA offers you the following modules:

- Technical consultation/machine audit

- Analysis of machine history

- Stock analysis

- Information about re-equipment and up-grades

- Training/workshops

Repairs

In cases where repairs are necessary, SIEBTECHNIK TEMA is there to help you to quickly restart your production operation. Joint analysis of the cause of damage is an important component of damage avoidance, that is, preventive maintenance. Often it is worthwhile to use a stand-by machine, in case of unscheduled stoppages.