Lamella Clarifier / Settler

Lamella Clarifier / Settler

The most effective settling tank solution

Gravity sedimentation is the most common and reliable method to separate suspended solids from liquids. It is used in nearly all water treatment, wastewater treatment, mineral processing and other processing plants. Traditional gravity settlers require large footprints and high capital investments. With the Siebtechnik Tema Lamella settler space requirements are reduced by 90% or more, at a fraction of the cost of a traditional settler, while operating essentially maintenance free.

It is a well known fact that the settling area is the most significant aspect of the settling capacity of any settler. With the inclined plate concept, the effective gravity settling area becomes the area of each plate projected on a horizontal surface. As a result, up to 10 square meter of settling area become available for each square meter of floor space occupied by the unit. This distinct advantage, when combined with the Lamella settler’s unique flow distribution and simplified sludge removal technique, insures optimum performance.

Our Lamella settler is commonly used in potable water and sewage treatment works, as well as the pulp and paper, chemical process, food processing, surface treatment, power, mining & minerals, iron and steel industries. Applications include the purification of raw water, primary and secondary effluents, re-use of process and backwash water.

Flowrates

Our standard Lamella settlers / clarifiers have an effective settling area between 15 and 150 m², allowing treatment of up to 150 m³/h per single unit. For larger flow rates multiple Lamella can be installed in parallel.

Our experienced engineers will advise you on which model is suitable for your application, based your specific feed water characteristics.

Material of Construction

We carefully choose the material of construction, depending on the unique site conditions and feed water characteristics, where the most common materials are:

- Epoxy coated mild steel

- 316 stainless steel

Optional extras

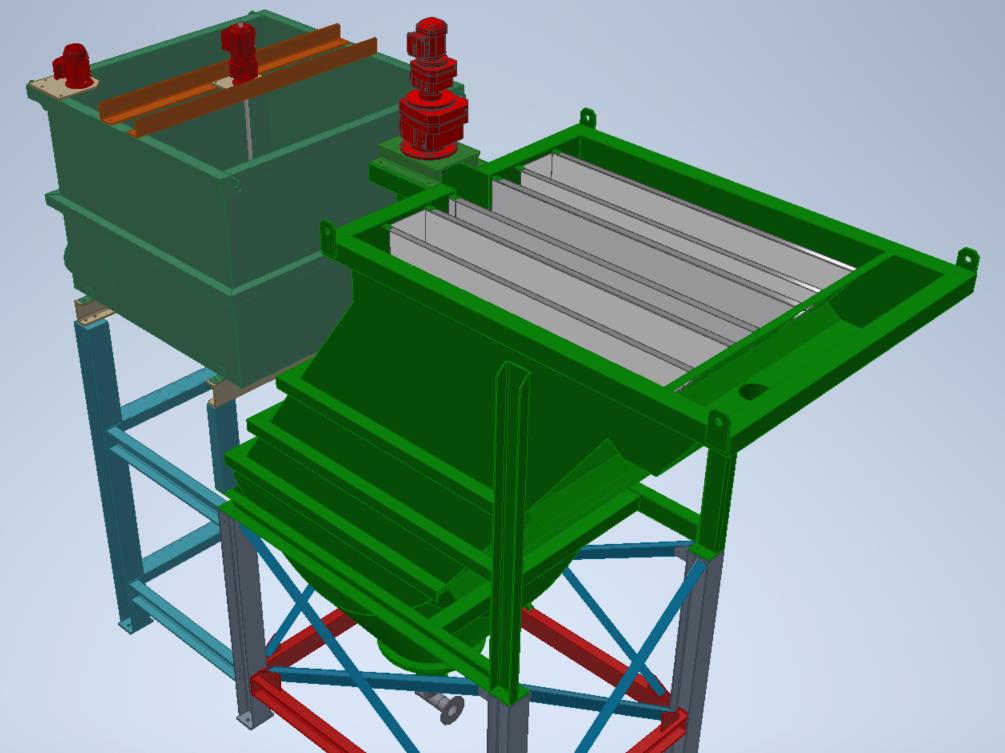

Our standard unit includes: Lamella plate packs (FRP plates/PVC sidebars), stainless steel internal launder system, sludge scraper, sludge scraper motor and gearbox. We generally offer the following optional extras:

- Flocculation system, complete with flocc tank and electric mixer

- Platform and staircase to provide access to the top for operational and maintenance purposes

- On site installation by our service technicians

- On site commissioning assistance by one of our engineers

Lamella packs for concrete tanks

Concrete tanks are ideal for high capacity installations. Installing Siebtechnik Tema Lamella plate packs in an existing settling tank is a simple and efficient solution to increase capacity in existing treatment plants.

Plate pack assemblies can be supplied as complete units ready for installation, reducing both the time and cost of the project. Settlers installed in this manner operate in exactly the same manner as free standing units, the solids settling on the inclined plates and sliding into the space underneath under gravity.

Advantages

SMALL AREA

- Occupies approximately one tenth the floor space or land area of a conventional clarifier

INSTALLATION COST

- Costs less on a total installed basis

SIMPLICITY / FLEXIBILITY

- Is factory pre-assembled, resulting in shorter deliveries and minimal field erection work

- May be installed indoors or covered at much less cost

- May be easily moved

- Has far fewer moving parts

- Is simple to start up and shut down

- Weighs Less

- Modular form allows easy expansion

- Can be free-standing or in concrete tank

- Is not affected by wind or thermal currents

OPERATING ECONOMY

- Low maintenance

- No spare parts