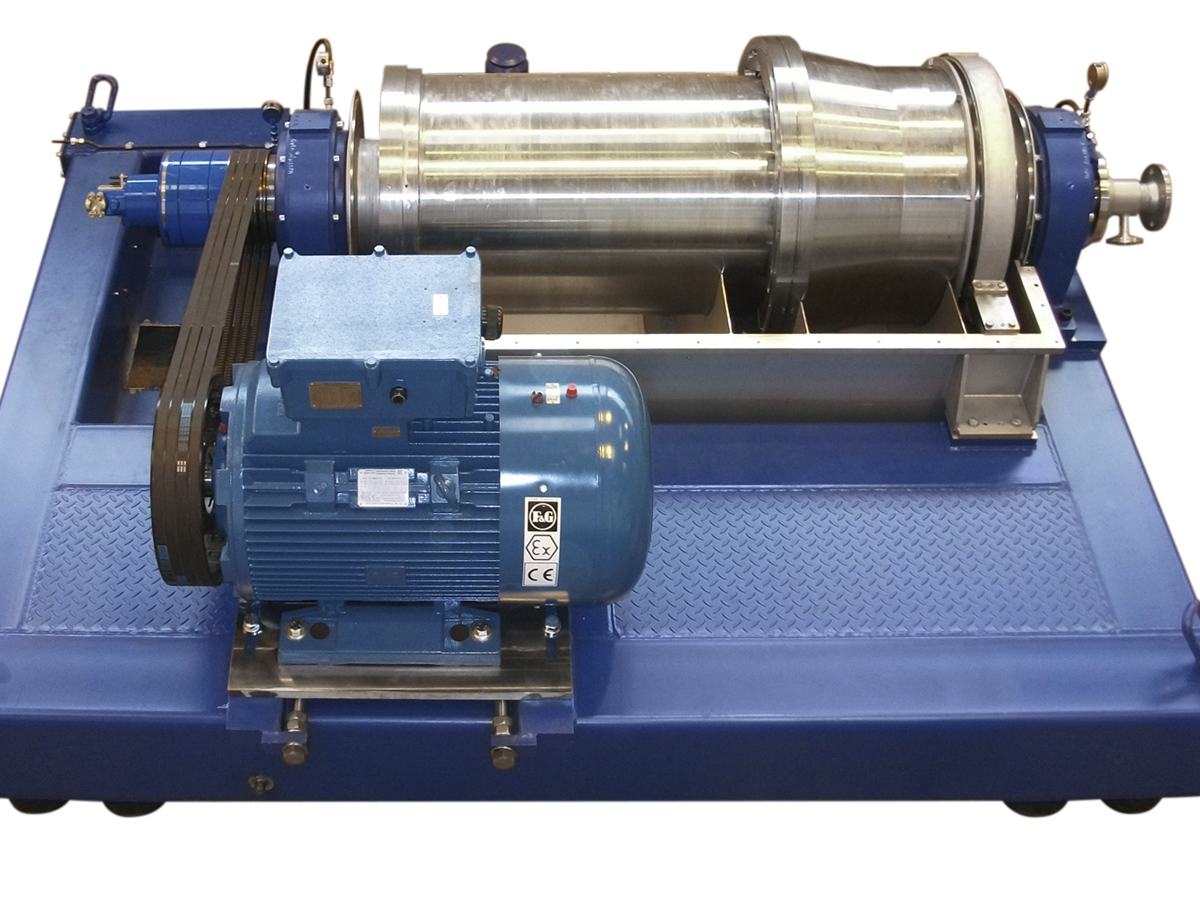

TWINCONE™ – decanter centrifuge

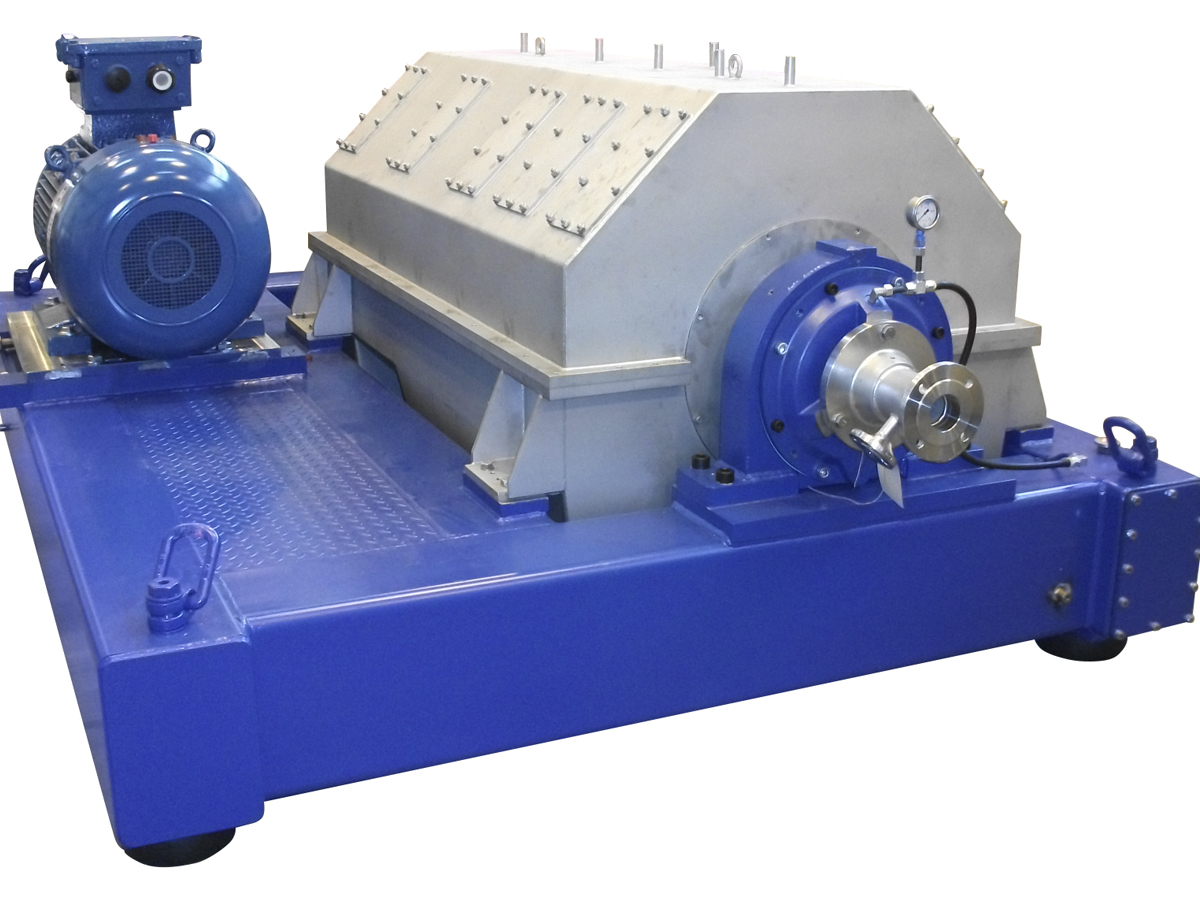

TWINCONE decanter centrifuge

Optimum washing in the decanter

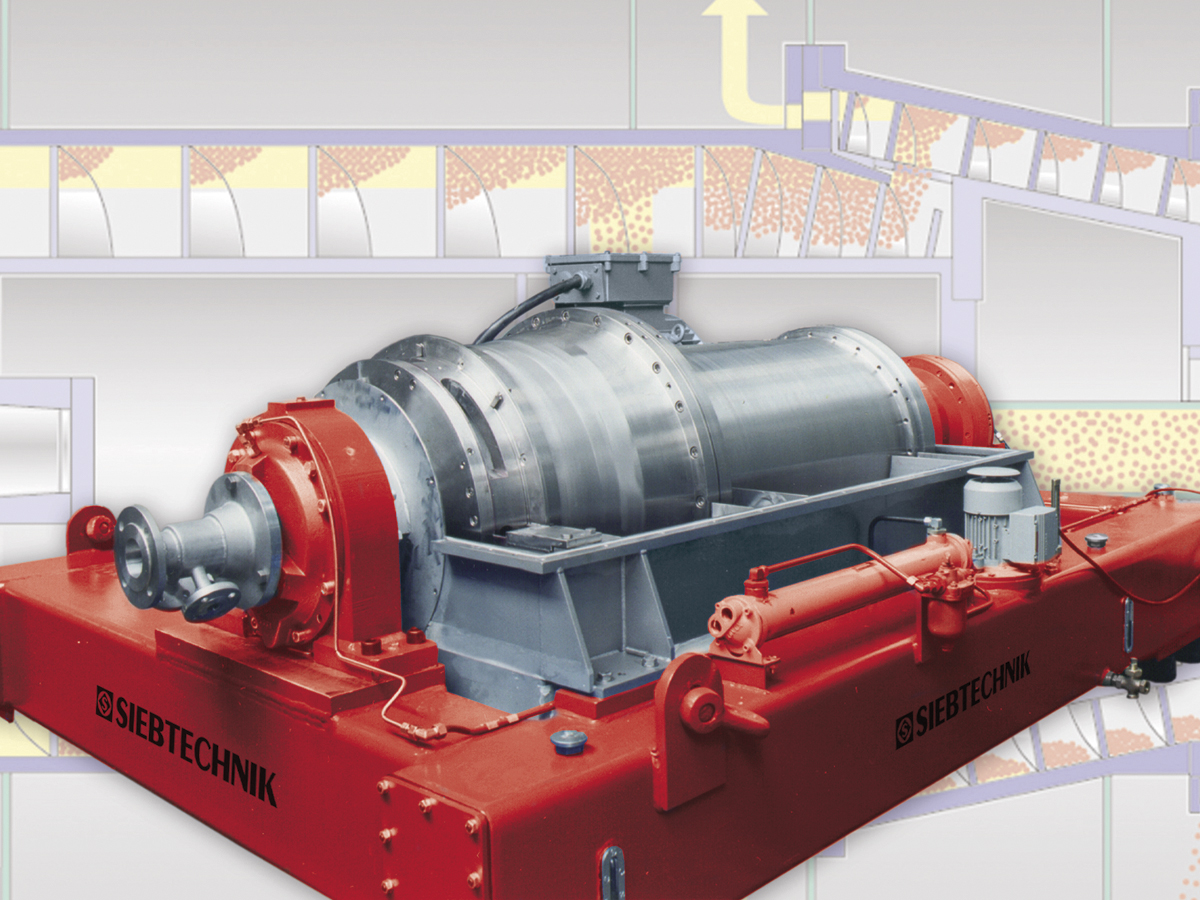

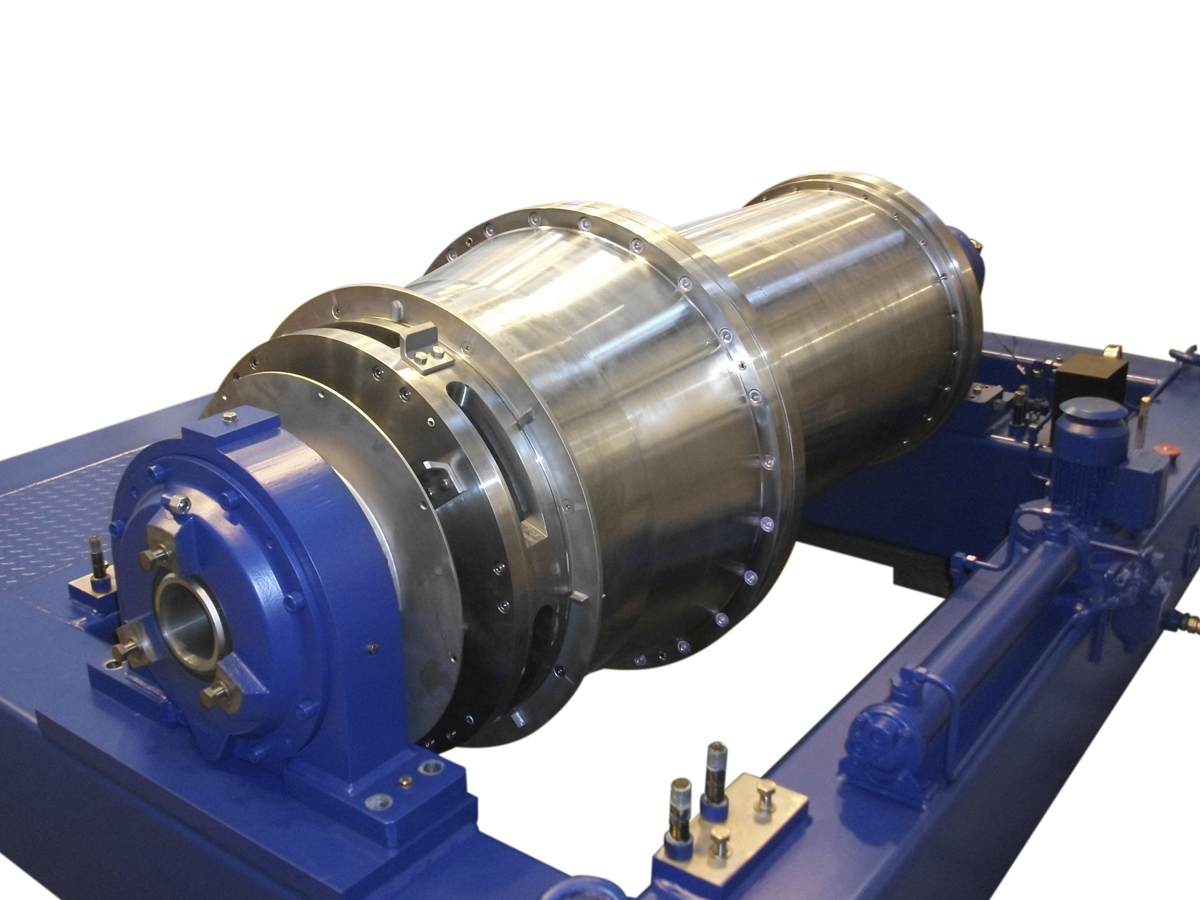

The sedimenting Siebtechnik Tema TWINCONE is a decanter centrifuge with a second bowl fitted downstream of the first bowl.

The solid matter is separated and concentrated by sedimentation in the first bowl. The second bowl has a larger diameter, thus a lower head of solid matter forms ahead of the scroll channel. On this second bowl the product can be washed, where the washing liquid drained off separately from the mother liquor.

Higher centrifugal forces are exerted on the particles in the second bowl, which greatly improves your dewatering. All Siebtechnik Tema TWINCONE decanters are individually customised to the client specific product conditions and system requirements.

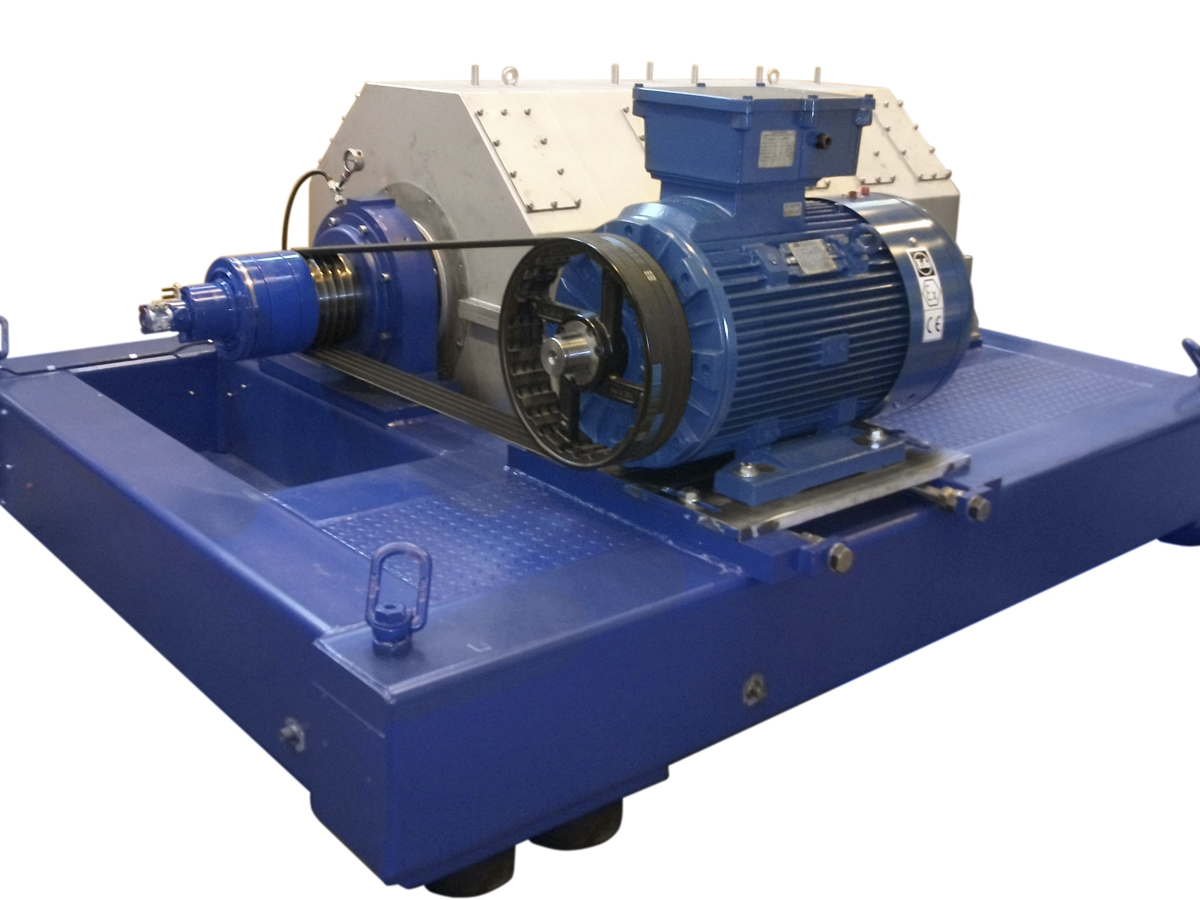

Operational behaviour and mechanical characteristics

The suspension is fed into the decanter through an inlet pipe and is then accelerated in a relatively small diameter clarification bowl, which is designed to suit clarification requirements.

The solid matter that has settled in the clarification bowl is pre-thickened. The filling volume of the bowl and therefore the length of the dewatering section can be adjusted by means of a weir plate.

The pre-thickened solid matter is discharged, over the discharge rim at the end of the clarification bowl, into a considerably larger dimensioned drying bowl downstream.

Here the solids cake is broken up and redistributed with a lower head of material, ahead of the scroll channel to match the larger bowl volume and smaller filling volumes between channels.

At the same time the larger diameter of the drying bowl guarantees high g-numbers at relatively low rotor speeds. The residual liquid is drained off through a separate liquid outlet in the centrifuge housing.

The solid matter carry-overs in the centrate are small, and due to internal recirculation within the centrifuge are not rated as a loss.

Product washing is also possible with the downstream drying bowl, where the wash fluid is drained off separately from the mother liquor.

Technical specification

| Decanter Centrifuge TWINCONE | ||||||||

|---|---|---|---|---|---|---|---|---|

| Type | TWC | 250/360 | 350/450 | 450/600 | 600/750 | 750/900 | 800/1000 | 1000/1200 |

| intermediate size on request | ||||||||

| Length | approx. mm | 2500 | 2800 | 3150 | 3350 | 4000 | 4200 | 4600 |

| Width | approx. mm | 1800 | 1850 | 2300 | 2500 | 2800 | 3000 | 3250 |

| Height | approx. mm | 920 | 1020 | 1300 | 1500 | 1800 | 1900 | 2100 |

| Weight | approx. kg | 1900 | 2650 | 4500 | 7000 | 11500 | 13500 | 18000 |

| subject to change without prior notice | ||||||||

Application

Advantages

- Continuous operation

- Washing with separate separation of mother liquor and washing liquid

- Wide range of applications in all areas of industry

- Flexible drive concept

- High machine availability

- Minimum maintenance

- Long service life

- Optimum adjustment of clarification and dewatering